Labeling your warehouse might seem like a straightforward task—until you realize how much it impacts everything from inventory accuracy to worker productivity. A poorly labeled warehouse can lead to misplaced inventory, slower picking times, and operational chaos. That’s why implementing a well-thought-out labeling system is critical for any efficient warehouse.

Whether you’re re-labeling an existing facility or optimizing a newly acquired space, this guide walks you through four essential steps to improve warehouse navigation, scanning accuracy, and scalability.

Why Warehouse Labeling Matters

Before we dive into the process, let’s clarify why warehouse labeling is so important:

- Reduces time wasted on locating inventory

- Improves order accuracy and pick rates

- Supports warehouse growth and new SKUs

- Enables FIFO/LIFO inventory flows

- Integrates seamlessly with WMS and scanning systems

Now, let’s break down the labeling process into actionable steps.

Step 1: Understand Your Storage Types

The first step is identifying what storage systems your warehouse uses. Most warehouses have a mix of:

Pallet Racking

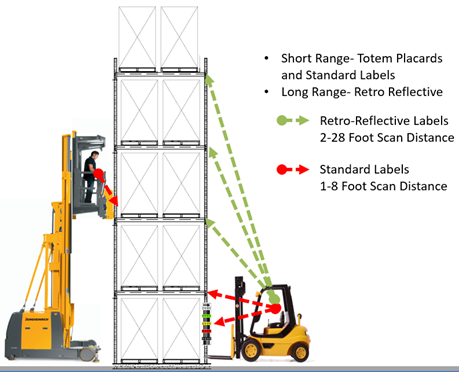

- Consider the height of the racks and scanning distance. For locations above 10 feet, retro-reflective labels are recommended.

- Color-coding by rack level (e.g., black for floor, red for second tier) can improve visibility and reduce errors.

- If rain guards or wire trays are present, labels must be placed in visible, scannable zones.

Step 2: Match Labels to Scanning Technology

We determine what your scanners need:

– Short-range scanners for shelf-level or elevated platforms

– Long-range scanners (up to 28 ft) for ground-based scanning on high racks

– Totem placards for vertical readability in narrow aisle applications

Step 3: Develop a Scalable Location Numbering System

We design a warehouse layout using structured codes:

- Warehouse ID → Aisle → Level → Bay → Slot

- Leading zeros for future expansion (e.g., 01-A-C-22)

- Color-coded levels and directional arrows for fast identification

- Excel templates and barcode-ready files for easy print/replication

Step 4: Select the Right Label Type

We supply and install rugged, scan-optimized labels that fit your environment:

| Label Type | Ideal For |

|---|---|

| Standard Rack Labels | Floor-level racks, general zones |

| Retro-Reflective | High racks, long-range scanning (above 14 ft) |

| Magnetic Labels | Temporary or rotating storage areas |

| Totem Placards | Dense rack aisles needing vertical visibility |

| Hanging Signs | Bulk and floor-stack zones with ceiling-mounted signage |

| Shelf Labels | Compact inventory on metal shelves |

Why Warehouse Labeling Matters — and Why 3PL Insight is the Right Partner

An efficient warehouse begins with clear labeling. When your staff knows exactly where to go and your scanners can instantly read the location, your operations gain measurable improvements: picking speed increases, inventory errors drop, and order accuracy sees a significant boost. In addition, training new staff becomes faster and easier, and the entire warehouse becomes more adaptable for future growth or SKU expansion. It’s a foundational step that influences everything from daily throughput to long-term scalability.

That’s where 3PL Insight delivers unique value. With over two decades of hands-on experience across hundreds of warehouse deployments, we understand the real-world challenges of distribution centers, fulfillment hubs, and 3PL operations. We don’t just drop in generic solutions — we engineer labeling systems specifically tailored to your facility layout, workflow, and scanning technology. From creating custom location sequences to printing durable, scan-optimized labels, our team ensures every detail is accounted for.

Whether you’re labeling pallet racks, shelving units, or bulk storage areas, we provide end-to-end support that includes barcode-ready label designs, Excel-based location mapping templates, and full implementation or guidance for in-house teams. Our expertise spans a range of environments including eCommerce fulfillment, pharmaceutical storage, cold chain logistics, and high-density warehouse operations.

At 3PL Insight, we believe your warehouse should be as smart and efficient as the technology that powers it. Our solutions are built for operational excellence — helping you reduce costs, improve labor efficiency, and future-proof your facility for the demands ahead.